How to Deliver Unified Customer Experiences Through Omnichannel Inventory

For today's customers, there is no difference between shopping online, in-store, or through social media. All they expect is a smooth and consistent experience at every touchpoint. When one decides to make a purchase, one might be looking for a product on a website, while another might be going to the nearby store to check its availability. In any stage, accurate information and reliable service are what matter.

However, it is very common among many businesses that they often struggle with fragmented inventory systems. For example, sometimes the availability of a product is shown as available online even after being out of stock in the warehouse. This sort of misleading information leads to many consequences, such as order cancellations, delivery delays, or dissatisfied customers, as it breaks the flow of the customer experience.

This is why omnichannel inventory management is needed, to connect all sales and fulfilment channels into one unified system. Let's explore why it is considered the foundation of a unified customer journey.

What is omnichannel inventory management?

Omnichannel inventory management is the process of managing and tracking inventory across all sales channels—online stores, physical retail locations, marketplaces, and distribution centres—through a single, unified system.

The term omnichannel itself signifies the strategy's aim of creating a holistic customer experience as it combines the Latin word "omni", meaning "all", with "channel,".

For example, a customer browses a website to check the availability of a limited-edition pouch at their nearest physical store. First, he/she reserves it online, and then picks it up in person the same day.

It is omnichannel inventory management that makes this level of integration possible.

The role of inventory visibility in customer experience

Inventory visibility is one of the key aspects needed to deliver a consistent and reliable customer experience. Once a business has real-time insight into stock levels across all sales channels, it can gradually minimise errors, improve transparency, and meet customer expectations more effectively.

Here's how inventory visibility can boost your customer experience,

It prevents overselling and stockouts

As it offers accurate and real-time data, customers don't end up purchasing items that are already out of stock. And for that, fewer order cancellations happen.

It ensures faster delivery

With up-to-date stock information, businesses can fulfil orders from anywhere, be it a warehouse, retail outlet, or third-party logistics provider, while ensuring faster and more predictable delivery times.

It improves transparency and trust

Customers can see real-time product availability before they make a purchase. Even once they order a product, they get real-time tracking updates, from checkout to delivery, which boosts their confidence in the brand.

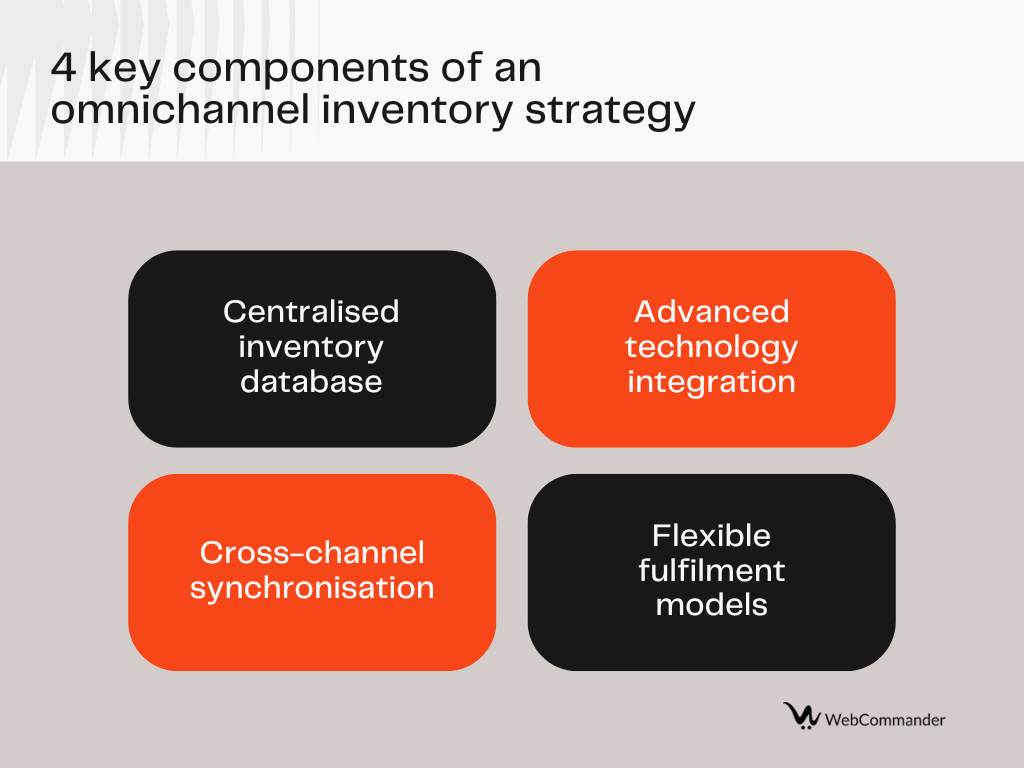

4 key components of an omnichannel inventory strategy

1. Centralised inventory database

A centralised inventory database works as a single, unified system and combines all inventory data from every channel. It serves as the single source that holds all data of a company's stock levels, movements, and availability.

It is a must-needed component for omnichannel retail because, in an omnichannel environment, customers interact with a brand across multiple touchpoints.

Without it

- Online stock may not be available at the same rate as in a physical store.

- Products can be oversold, leading to cancellations.

- Staff may spend hours manually, which might increase the rate of inefficiencies and errors.

2. Advanced technology integration

Technologies such as automation and artificial intelligence (AI) can replace all the manual processes and streamline and optimise inventory operations with data-driven systems.

In omnichannel inventory management, they ensure that

From updating the stock levels to forecasting the demands to processing the orders, integrating smart technologies can benefit in many ways. It ensures speed and accuracy with minimal human intervention.

Otherwise, managing inventory across multiple sales channels, online stores, marketplaces, mobile apps, and physical locations turns quite complex.

It is automation and AI that simplify this by:

- Continuously tracking the stock movements in real time.

- Predicting demand depending on customer trends, seasons, and historical data.

- Automatically triggering restock or redistribution of inventory whenever needed.

3. Cross-channel synchronisation

Cross-channel synchronisation helps in keeping inventory data consistent and updated in real time. It ensures that whenever a customer views, buys, or returns a product through any channel, it instantly updates the number.

Eventually, it eliminates the information gap that often occurs between systems. Also, it enables seamless coordination between front-end shopping experiences and back-end inventory operations.

Otherwise, when there is no proper synchronisation, many channels end up operating in isolation, leading to:

- Inaccurate stock levels are shown to customers.

- Double-selling or unavailable products.

- Creating confusion among the staff.

4. Flexible fulfilment models

It refers to the system where the customer orders can be completed from multiple locations and through different methods, such as warehouses, retail stores, third-party logistics (3PL) providers, or even suppliers directly.

The key target is to offer convenience, speed, and choice to the customers while optimising logistics and operational efficiency for the business.

Modern shoppers expect to receive their purchases as per their preference. So, if your business only relies on a single fulfilment model, it can't meet these expectations, especially during high-demand periods or supply chain disruptions.

But if you maintain a flexible fulfilment strategy, you can adapt quickly, prevent delays, and maintain a seamless customer experience.

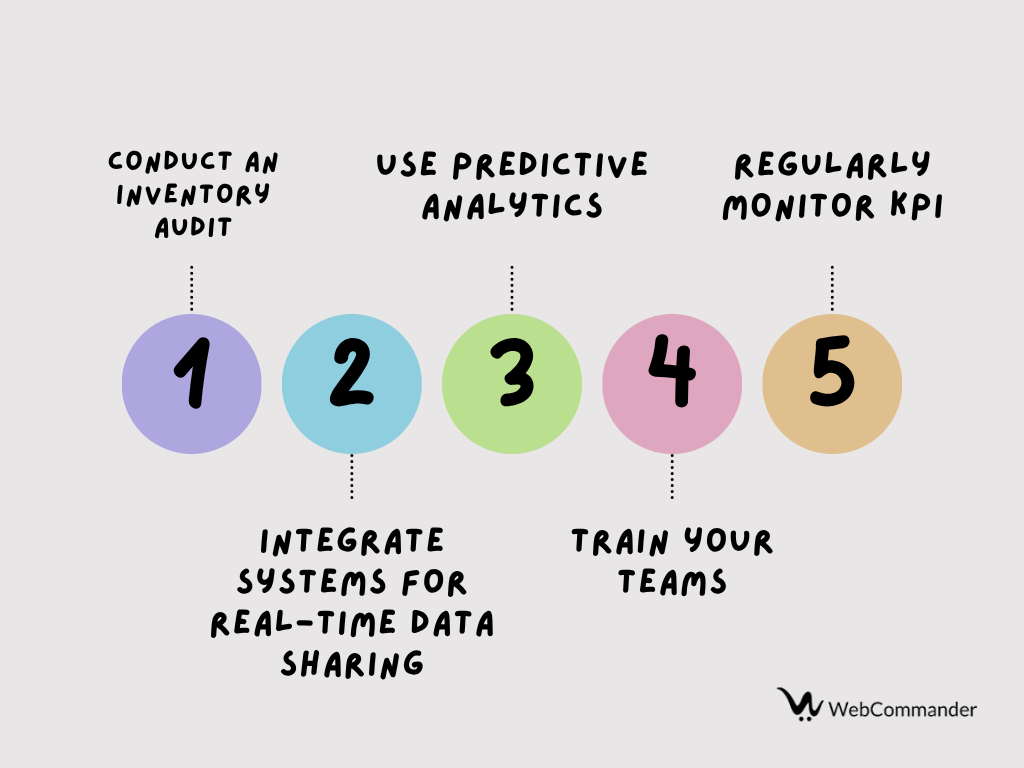

Implementation best practices

Implementing an effective omnichannel inventory management system involves a structured and data-driven approach.

Here are five best practices you can implement,

1. Conduct an inventory audit

You can start by performing a comprehensive audit of your existing inventory systems. This will help you uncover inefficiencies that you need to deal with. It can be overstocked items, slow-moving products, or inconsistency between your physical and recorded inventory.

Once you can identify these gaps early, you can set a more accurate baseline for integration and ensure that all systems reflect real, actionable data.

2. Integrate systems for real-time data sharing

True omnichannel success depends on seamless integration between your point of sale (POS), enterprise resource planning (ERP), customer relationship management (CRM), and ecommerce systems. If these platforms communicate in real time, you will get a single, unified view of inventory across all channels.

Also, you can maintain consistency in terms of product availability, pricing, and order statuses. So, there will be fewer stockouts, miscommunications, and customer frustration.

3. Use predictive analytics

Track all the past purchasing trends, seasonal patterns, and emerging market behaviours to anticipate your customer demand. You can use AI-driven forecasting tools to optimise stock levels.

This way, you can ensure improvement in product availability and reduction in carrying costs, while directly enhancing customer satisfaction.

4. Train your teams

Technology can only deliver results if your team can understand and utilise it properly. You have to provide proper training to everyone involved, including sales associates, warehouse staff, and customer service teams, so that they can navigate new systems confidently.

Build up collaboration between departments so that online and in-store teams can share updates and align on order fulfilment, returns, and other processes.

5. Regularly monitor KPI

Measuring performance can help you maintain visibility into operational efficiency and customer experience. For example, the stock turnover rate will reveal how effectively inventory is being sold, while the fulfilment time will refer to how quickly orders can be processed and delivered across channels.

Once you start monitoring your performance regularly, you can easily identify bottlenecks, track progress, and continuously improve your system while staying aligned with customer needs and market dynamics.

Wrapping up

So, one thing is certain: integrating omnichannel inventory systems cannot be taken as an optional choice; it's a must to follow for maintaining consistency, transparency, and trust across every customer touchpoint.

Looking ahead, organisations that master unified inventory management will stand out in an increasingly competitive retail landscape. So, invest in real-time visibility, system integration, and predictive insights to boost customer satisfaction and brand loyalty for the long term.

![How to Start an Ecommerce Business in Australia [2023 Guide]](/template/e27cf56f/images/resource-blog-right-img1.png)